Material Testing & Certification

Due to the heavily regulated nature of many of our customers’ industries, it is essential that we supply only the materials that we specify. We provide material testing and to meet international quality compliance regulations.

Material Testing and Certification Service

In heavily regulated industries, it is critical that we only supply the stated materials. We can supply X-Ray Testing certificates to confirm the grade of stainless steel, and Surface Finish Analysis certificates to prove surface smoothness.

TSE certification is also available upon request, to state that no animal fats have been used in the polishing process. This is vital to guarantee that no cross-contamination from BSE or CJD diseases occurs.

Using specialist testing and analysis equipment, we offer a cost-effective material testing service, backed up by comprehensive certification where required. This service gives you the peace of mind that you are getting what you are paying for, undertaking due diligence, and ultimately maintaining your quality control.

What is Material Testing?

Our Material testing service is the non-destructive, highly accurate process of testing stainless steel products to determine the elemental composition matches the requirements for each grade. Adelphi supply product ranges in two types, known as 304 and 316L grade.

304 is an excellent general grade of stainless steel, suited to a range of uses. It has a minimum of 18% chromium and 8% nickel, combined with a maximum of 0.08% carbon. It is defined as a Chromium-Nickel austenitic alloy.

316L is, however, recommended for pharmaceutical, cosmetic, food and dairy applications, as it has an even better corrosion resistance than 304 grade. 316 grade stainless steel is an austenitic form of stainless steel known for its 2-3% molybdenum content. The added molybdenum makes the metal more resistant to pitting and corrosion, as well as improving resistance when exposed to elevated temperatures.

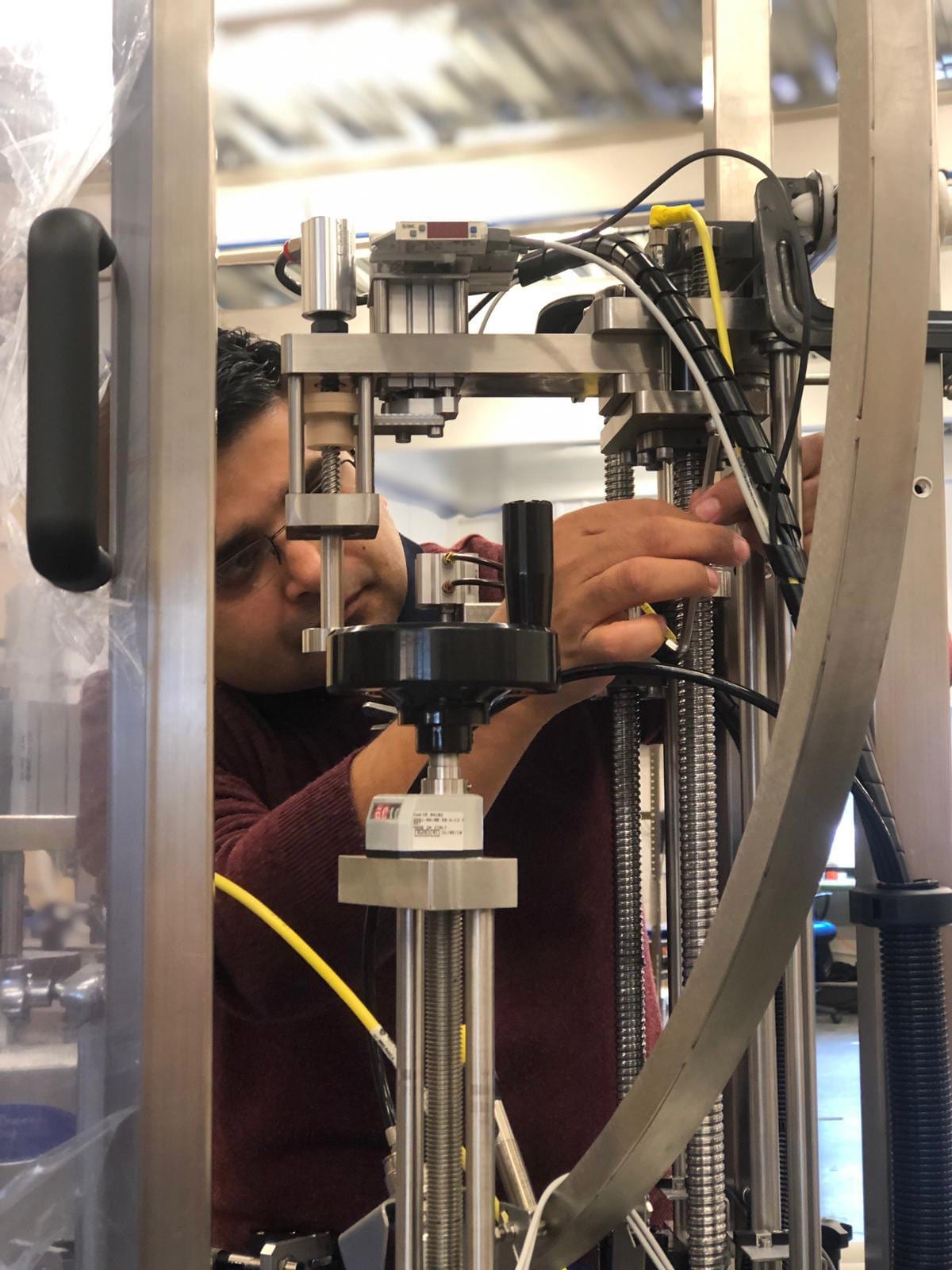

All 316L grade items supplied by Pharma Hygiene Products are tested in-house using an X-ray analyser (see image above), which confirms the grade of stainless steel, providing reassurance of the highest quality. Certificates confirming the grade and composition of stainless steel can be supplied on request at an additional cost.

XRF Testing – X-Ray Testing Certificates

XRF Testing is carried out by an X-Ray Fluorescence (XRF) gun, to detect fake or non-confirming metals. The benefit of a XRF gun is that is leaves no visible spark site so the equipment’s finish is not compromised. The XRF gun measures to metals components (cr, mn, fe, ni, cu, mo) to ensure the material is genuine and meets regulation requirements.

Once we have tested the material we will produce you a certificate to confirm the results. When testing on site, Adelphi always prevent access to areas where X-Rays are used to ensure the safety of all staff and visitors. Only staff who have had specific radiation safety training are allowed to operate XRF testing guns.

Did you know that XRF guns can also be used to test for banned substances in plastics? An example of banned materials in plastics includes mercury in Europe.

TSE Certification

TSE certification is also available upon request to state that no animal fats have been used in the polishing process. This is vital to guarantee that no cross-contamination from BSE or CJD diseases occurs. TSE stands for Transmissible Spongiform Encephalopathy.

TSE compliance certificates are a type of Certificate of Suitability to the European Pharmacopoeia, used to maximise safety when working with materials that could potentially be contaminated with TSE.

Contact Us To Ensure Quality Control with Adelphi Material Testing

To receive an XRF certificate, simply request it on a purchase order or when speaking to a member of our team for a quotation.

Get in touch today for our material testing service by using the contact form below.

Adelphi aims to deal with all enquiries within 24 hours. We thank you for your patience.