Filling Machine Maintenance

Timely machine servicing identifies and resolves faults during a maintenance schedule, and not in the middle of production. The cost of regular maintenance is minimal when compared to the cost of a major breakdown which could halt your operations entirely.

Liquid Filling Machine Servicing

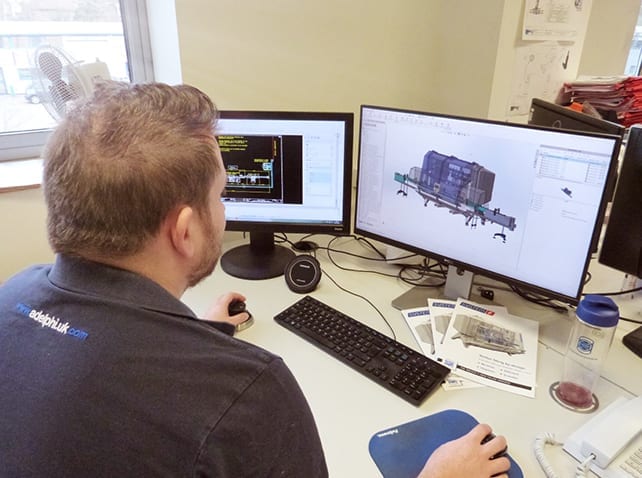

The Adelphi Group of Companies is able to provide expert and cost effective filling machine servicing for each piece of machinery and equipment that we sell, wherever you are in the world. In many cases we organise annual visits to a region during which we visit a number of customers in one area. By doing so, travel costs are shared, thereby keeping costs down, whilst getting the benefit of having a highly trained Adelphi service engineer keeping your machine working as it should.

You are welcome to book our liquid filling machine servicing as and when you require it, however we would always recommend a scheduled service at least once every twelve months.

BOOK A MACHINE SERVICE using the contact form below…

Enquire about servicing

What is Machine Maintenance?

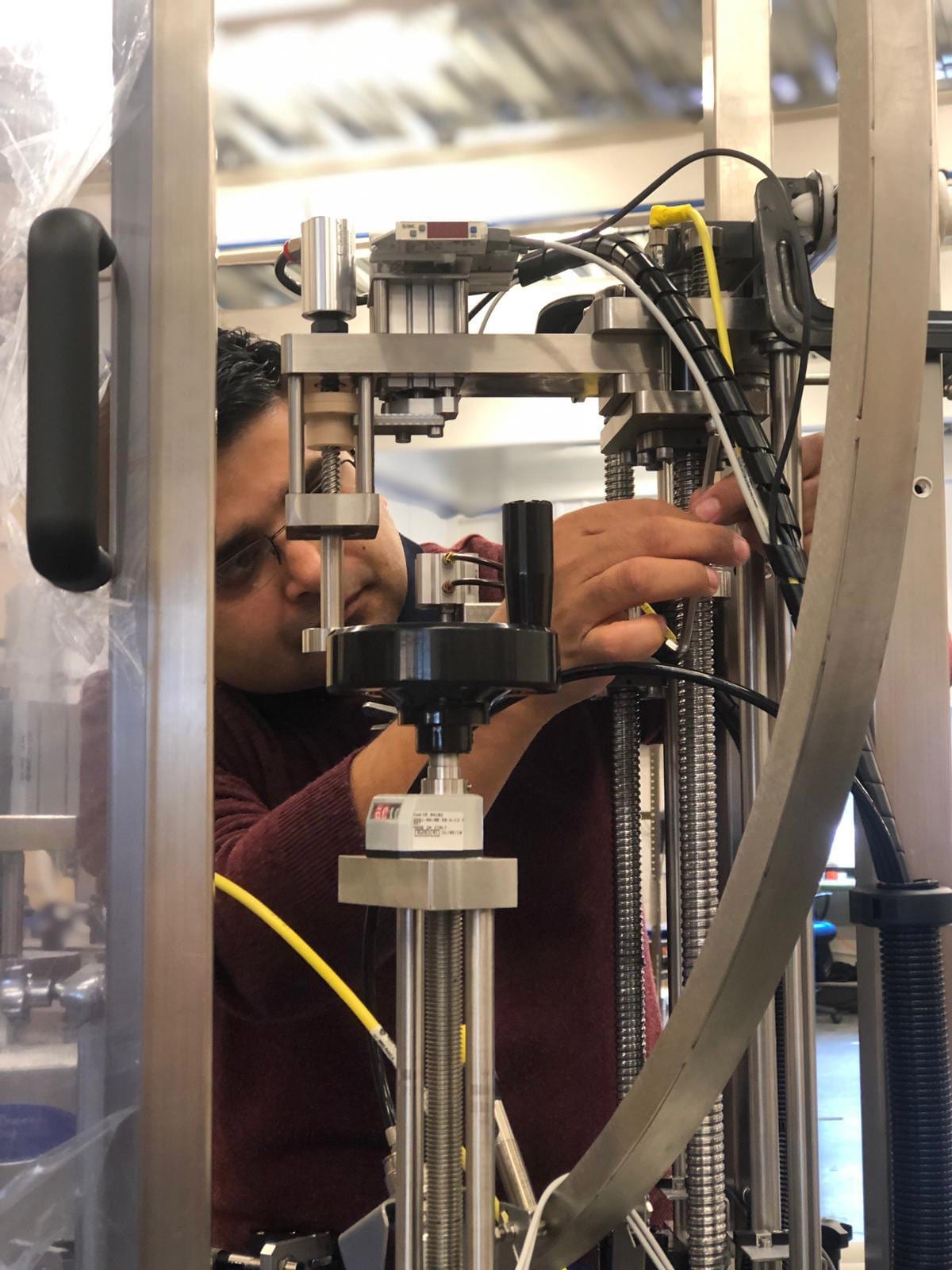

Machine maintenance is the process of keeping filling machines in the best possible condition. Machinery maintenance involves regular servicing of equipment, routine checks, repair work, and replacement of worn or non-functional parts.

Why is Machine Servicing Important?

Without regular and proper maintenance, machines can become unsafe or develop increasingly regular faults over time. Although our machine servicing team are extremely experienced and proactive, we are unable to always guarantee that an engineer will be available immediately, should your machine experience any issues. The cost of regular maintenance is minimal when compared to the cost of a major breakdown, which could halt your operations entirely.

Many of our customers’ machines are still fully operational over 30 years after purchase. Regular and preventative machine servicing, maintenance and machine servicing keeps your equipment working as it should, for as long as possible, to maximise your return on investment.

Types of Filling Machine Maintenance

There are various types of machinery maintenance including:

Reactive, Corrective, Preventive and Routine maintenance

You can read details on each type of filling machine maintenance below…

“Adelphi are always attentive to any issues that may arise, and are only a phone call away.”

McCavity’s Contract Fillers

Reactive Maintenance

Reactive machine maintenance, also known as breakdown maintenance, is conducted in response to a breakdown. This type of maintenance will restore the equipment to its normal working condition.

Adelphi is always on hand to assist with reactive maintenance. However, we much more strongly recommend proactive, preventive maintenance and regular machine servicing to avoid the drawbacks associated with reactive maintenance…

The main negative aspect of reactive maintenance is that it’s a more expensive option, as production is at a complete halt until the machine is running again. This may result in production delays, late orders and have an impact on your company’s revenue and reputation. Adelphi tries to have engineers on-hand in case of emergency breakdowns, however, engineers and the spare parts required may not always be available the very next day.

Reactive maintenance does not help towards improving the life span of your filling machines; although Adelphi’s engineers are able to get your machines up and working again; we cannot guarantee that they will perform “as new”. If you only perform reactive maintenance, you may find the machine performance deteriorates faster than when using preventive maintenance.

To find out how to optimise your machines lifespan, scroll down to our preventive maintenance section…

Corrective Maintenance

Corrective maintenance is the process of detecting an issue whilst performing another maintenance task on a machine, and arranging for the problem to be sorted when first spotted. Similar to preventive maintenance, the difference is that corrective maintenance is not part of a routine inspection.

For example, if you are performing an emergency repair as part of reactive maintenance on the machine and notice visible wear on a separate component of the machine, you should organise to deal with the problem immediately.

The benefit and purpose of corrective machine maintenance is to reduce reactive maintenance requirements, saving you money. You are also assured of optimal operator safety when the machine is in the best possible condition.

Preventive and Routine Machine Servicing and Maintenance

Preventive maintenance, also known as preventative machine servicing, includes the routine procedures that are completed on a regular basis to catch and fix problems before they actually occur. A routine machine inspection, conducted a few times a year, should be enough to detect an issue before it becomes a problem.

If you are carrying out an inspection and notice a part such as a seal, O ring or other mechanical components, which looks to have signs of wear and tear, you should replace these immediately. Due to the current global shortage of some parts, you don’t want to risk an unexpected breakdown simply because you didn’t change you seals when you first noticed the damage.

Creating a preventive maintenance schedule ensures the inspections are never forgotten. Benefits include maximising your machine’s lifespan, and reducing unexpected downtime.

Adelphi always recommends preventive machine servicing and maintenance to achieve the best performance from your filling machine. If you look after your filling machine, it will look after you in return.

How to Improve Machine Maintenance

If you think that you need to start looking at preventive servicing but are unsure of where or how to start, Adelphi are here to support you throughout the process with some useful tips.

Firstly, we would recommend organising an annual machine servicing from the time when your machine is one year old. It may seem strange to have to service your machine so early on, and there may be very limited suggestions made for improvement – especially if you are on top of cleaning out your filling machine after each production run. However, this is the best method to keep your equipment in the best condition for optimal lifespan.

Having critical spare parts on site, including O rings, piston seals and other high-wear components is also a great way to prevent production coming to a halt when they need changing.

Regularly stripping-down and cleaning your machine is the best way to anticipate which parts of the machine are likely to need replacing, before the situation becomes crucial. Unsure of how to do this? Ask our team of experts using the contact form above.

Planning regular inspections is another way to protect against breakdowns. The cost of regular maintenance is minimal compared to the cost of a major breakdown, which could halt your operations entirely.

Adelphi regularly promote the importance of machine servicing, and provide other helpful hints and tips, in our Newsletters. To sign up, simply add your email address to the ‘Stay up-to-date’ section at the bottom of this page!

Ensure Machine Maintenance with Adelphi

- Would you like to receive further support with your machine maintenance?

- Want to book in your annual service?

- Need to order spare parts to have them readily available on site?

Contact us using the form below to be put in touch with an industry expert…

Adelphi aims to deal with all enquiries within 24 hours. We thank you for your patience.