Filling Machine Repair

Over time, the efficiency of any machine will reduce, regardless of how comprehensive your servicing regime is. Our filling machine repair and refurbishment services can offer a cost-effective solution by upgrading and modernising key components.

Machinery Repair

A reduction in efficiency is inevitable over time, as key machine components wear to the point that they are no longer within their design tolerance. However this needn’t lead to heavy investment in new machinery; Adelphi regularly refurbishes and repairs Masterfil filling and capping machines all over the world.

Initially we will carry out a machine survey on-site, and provide you with a budget quote for machine repair and refurbishment. Upon acceptance, we will strip down your machine, replace all worn parts, upgrade the control system if required, and generally bring your machine back into line with its original operating specifications. Often we are able to better the original outputs, especially if we are given the go-ahead to replace the control system with a more modern equivalent.

Whilst we like to sell new machines, we do recognise that this is not always possible, or indeed necessary. Filling machine repair or refurbishment can often be a more cost-effective solution.

What is Filling Machine Refurbishment?

Machine refurbishment is the process of stripping, inspecting & replacing any damaged or worn parts and reassembling a used machine (one that might not have been serviced previously) to restore your equipment to full working order. Changes to the machines design, function or safety may be required to meet regulations and your increased productivity needs.

In some cases, this may be as simple as a seal changeover if your product is wearing down seals quickly and in others, there may be a lengthy process of changing individual components. Here are some examples of general machine repairs and refurbishments we offer:

- Repainting of a machine – the machine may have become worn over time or you may be looking at rebranding and require a different colour scheme.

- Undertaking servicing and routine maintenance – servicing is recommended on an annual basis. Read more about our machine servicing.

- Changing or replacing motors – your motor may be louder than before or you may be experiencing untimely breakdowns.

- Replacing machine parts – this may include guards and safety elements.

If machine refurbishment is applicable to you, here are some of the benefits:

- Save time (and potentially money too) as you don’t have to train operators on how to use a new machine.

- Avoid the associated risk of long lead-times on a new machine.

- Save the cost of buying a new machine.

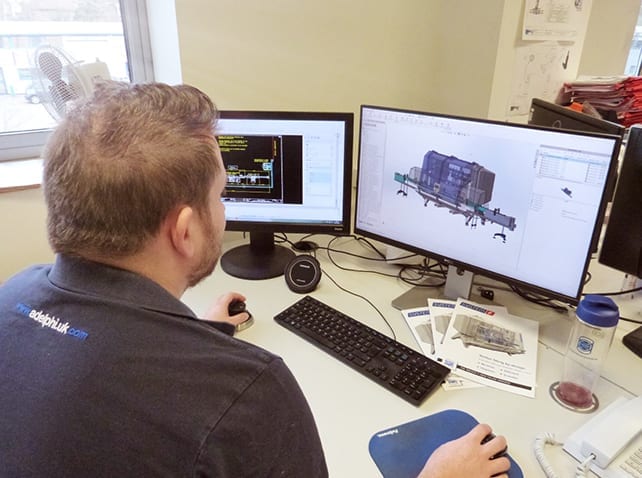

Adelphi has a team of experienced engineers available to service, repair and refurbish your machines.

“Thank you very much for the quick support. Only wish we had contacted you earlier. The machine is now performing very well.”

Merck

Does your Filling Machine Need Repairing or Refurbishing?

- Are you noticing inconsistency in fill weights?

- Are you experiencing dripping or stringing from filling nozzles?

- Have you put off small maintenance tasks for a long time?

Either of these small factors can result in product being lost through time-consuming mess in the production area, as well as through costly over-filling.

To assess your current equipment, you should take the following factors into consideration:

• Age – older machines are not able to compete with newer models, especially in terms of speed and versatility.

• Downtime – how much downtime are you currently experiencing as a result of maintenance issues? It’s suggested that if you are spending more than 10 hours a month on repairs, you should invest in refurbishing or a new machine or a machinery repair service.

• Maintenance costs – Investing once in a refurbishment is more cost-effective than constantly paying a supplier for maintenance.

• Are parts available? – You may find that replacements parts are becoming less available than before, the current worldwide shortages means you could be finding yourself in a breakdown situation for a significant amount of time.

• Following trends – is your machine adaptable in the same way as newer machines? You don’t want to appear as a company that can’t keep up with trends because your machine is not compatible with certain products or materials.

• Error costs – if your machine is significantly over filling products you may have to re-do orders costing you time and money.

Adelphi are here to offer you the services and support required to ensure your productivity is not being compromised by easily avoidable threats. If these threats sound familiar, get in touch via the contact form below, so we can get your filling and packing machines repaired or refurbished.

Machine refurbishment or repair is not always the most appropriate step for some companies. For example, when considering refurbishment we will always consider machine age, as older styles may have discontinued components and are not be compatible with newer parts.

In those cases, we might suggest investing in a new machine which will actually work out as the more cost-effective method.

Liquid Filling Machine Repair With Adelphi

Does the above sound all too familiar? If you want to investigate all your liquid filling machine repair and refurbishments options, simply fill out the contact form below!