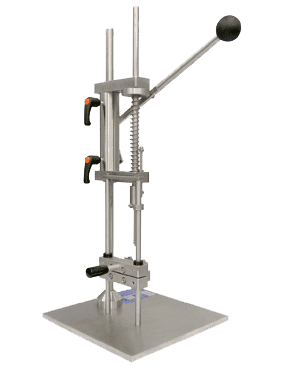

Manual Syringe Stopper Press

Simple & Intuitive Operation

Fully Adjustable for Operator Safety

Delivery Within Days

Product Specification:

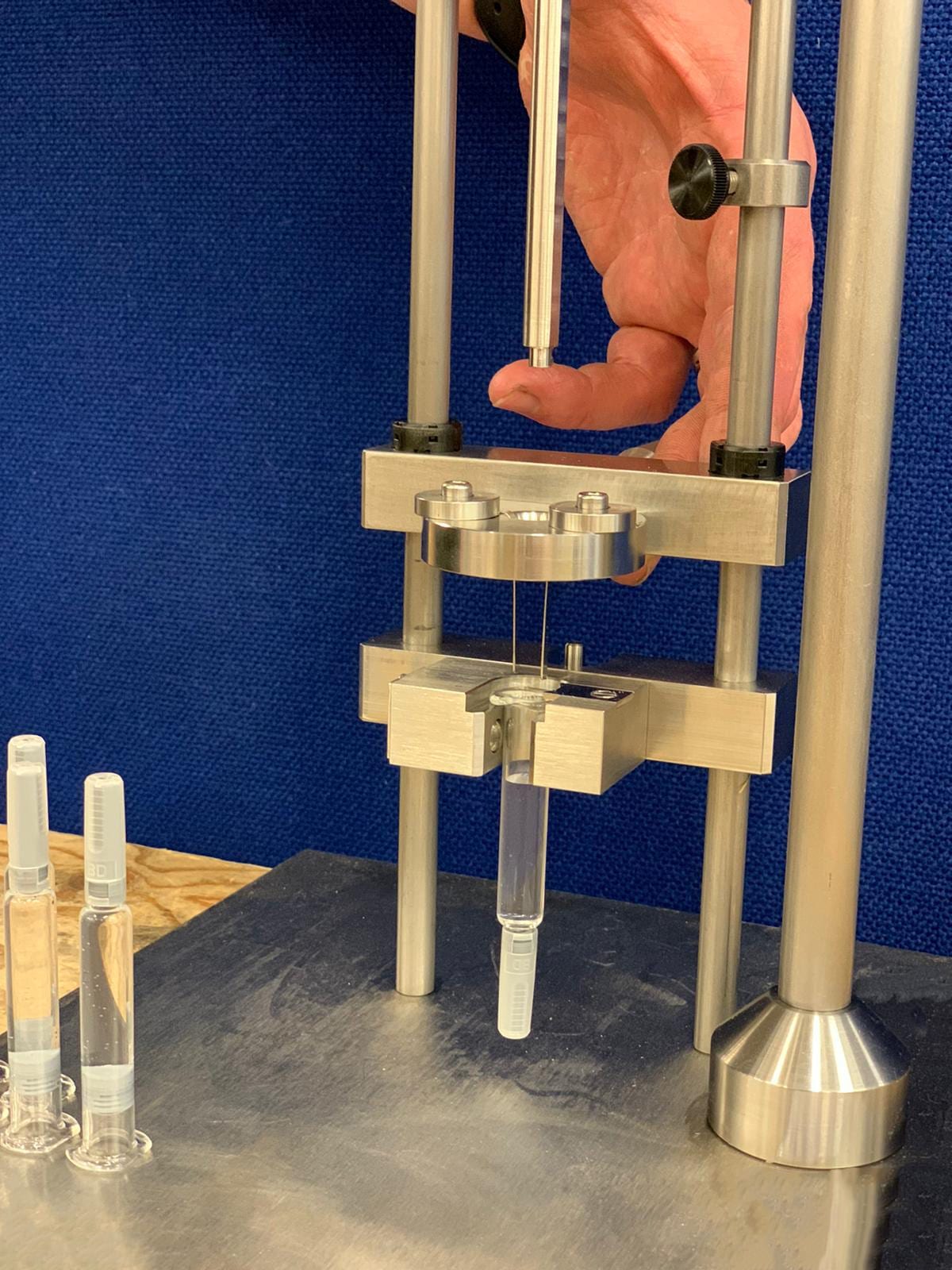

- To accommodate glass or plastic syringes of 6.35mm bore or greater.

- Easy and efficient insertion of stoppers into pre-filled syringes, ensuring that all air is expelled.

- Hygienic 316L pharmaceutical grade stainless steel contact parts, to eliminate the risk of contamination.

- Fully adjustable design for operator comfort and safety.

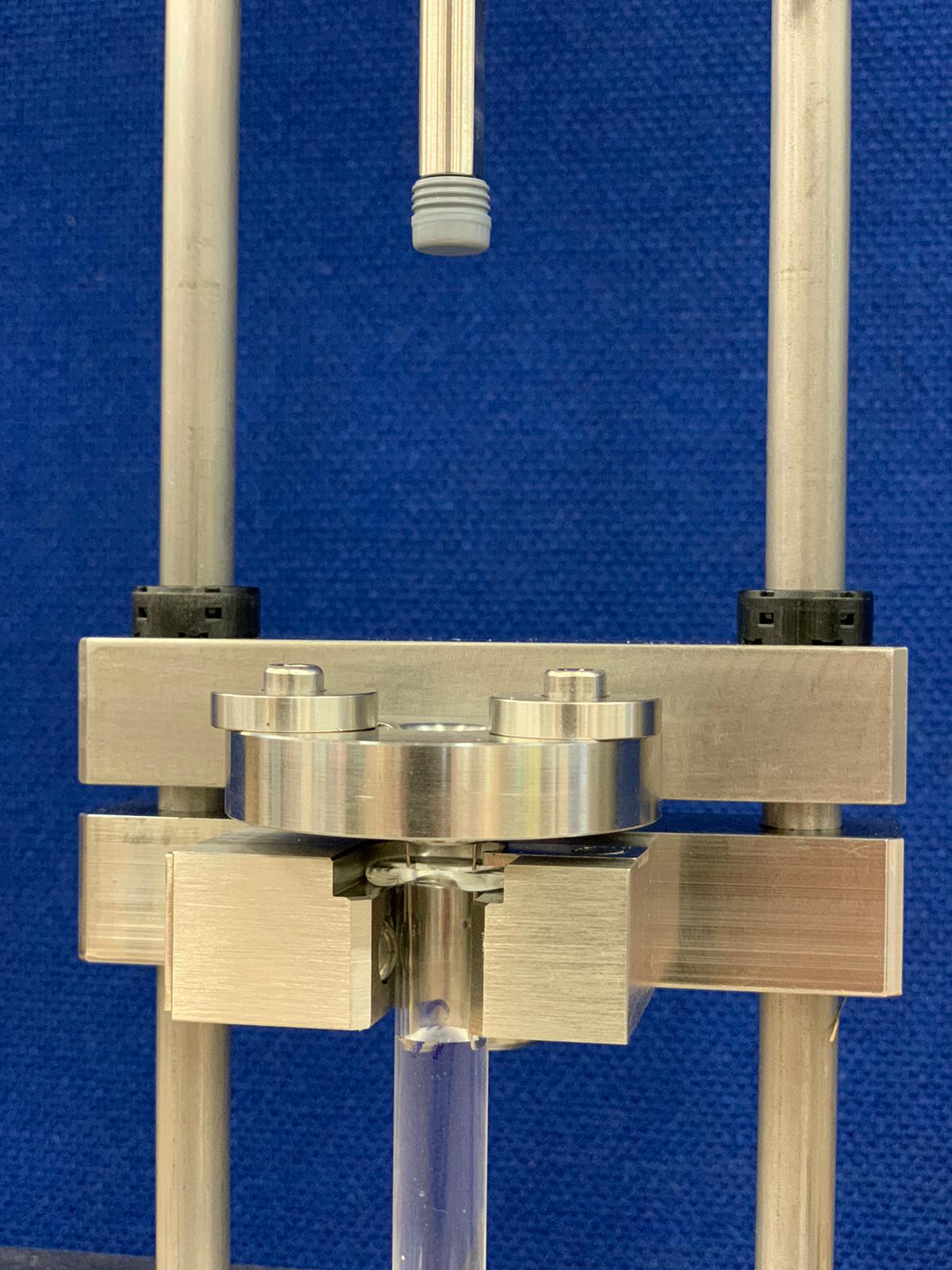

- The unit comprises a syringe holding jig, lever operated stopper press, and a divide for aiding the removal of air from the syringe.

Adelphi Manufacturing also offers the

Accuramatic Peristaltic Dispensing Unit,

for filling nested syringes

Pricing:

| Product No. | Description | Material | Price |

|---|---|---|---|

| SP048-3001 | Manual Syringe Stopper Press | £4713.00 | |

| SP048-3001-CP2 | Additional Pair of Bleed Strips | £107 | |

| SP048-***-CP | Set of Change Parts to process a different size of syringe | £1602 |

Contact us about this product

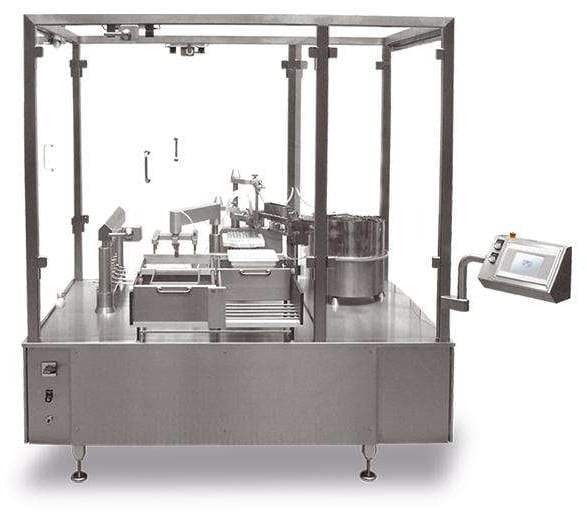

Syringe Stopper Press

The Adelphi Syringe Stopper Press enables the user to easily and efficiently insert stoppers into pre-filled syringes whilst ensuring that all air is expelled. It comprises a syringe holding jig, lever operated stopper press, and a divide for aiding the removal of air from the syringe. All contact parts are manufactured from 316L grade stainless steel.

Types of Syringe Stoppers

Adelphi offer a manual syringe stopper, as well as being an agent for ROTA fully automatic syringe fillers and closers.

Ideal for small batch numbers the Syringe Stopper Press is intuitive & simple to operate, it is also fully adjustable for optimal operator safety.

The Benefits to Your Production

Quick & Efficient

- Efficient insertion of stoppers into pre-filled glass or plastic syringes, of 6.35mm bore or greater

- Robust and reliable, for a professional quality finish every time

- Compact, space-efficient footprint, to conveniently fit on a small workbench.

- Simple and intuitive functionality – get started right away!

Exceptionally hygienic, international pharma-quality compliant

- The process ensures that all air is expelled from the syringe

- Hygienic 316L pharmaceutical grade stainless steel contact parts, to eliminate the risk of contamination

Stoppers vs Fillers

There is a variety of syringe processing equipment readily available from Adelphi Manufacturing to support your syringe production. Our solutions assist with all stages of production:

- Syringe Washer

Our Bottle/Vial/Syringe washer is highly efficient; producing up to 900 containers per hour:

- For container neck diameters between 9.5 mm and 100 mm

- Thorough cleaning; jets of water clean every part of the container interior

- Interchangeable nozzles so the unit can be used to wash bottles, vials, syringes and/or test tubes

- Four armed container rests are easily cleaned or replaced.

- May be attached to the mains directly by plumbing, or on a stand with a pipe connected to a tap.

- Syringe Filling

Adelphi Manufacturing offers a range of syringe filling equipment to suit your production size and requirements. You read more about syringe filling and processing on our product page

- Syringe Stoppers

Adelphi Manufacturing’s Syringe Stopper Press provides easy and efficient insertion of stoppers into pre-filled syringes of 6.35mm bore or greater

- Syringe Inspection Unit

Adelphi Manufacturing’s ‘Apollo ‘ Liquid Inspection Range consist of 4 units, each designed with a specific purpose in mind:

- Apollo I Liquid Viewer – with 1.7x magnification

- Apollo II Liquid Viewer – EU & US pharmacopoeia compliant, for transparent containers

- Apollo II High Intensity Liquid Viewer – EU & US pharmacopoeia compliant, for transparent containers

- Apollo II Dimmable Liquid Viewer – EU & US pharmacopoeia compliant, for transparent containers

The Benefits for Your Production:

- Simple particulate detection; in front of the black panel, light particulates will be visible, and in front of the white panel, dark particulates will be visible

- Height and angle adjustable for operator comfort

- Get started right away; intuitive assembly, with no tools required

- Bulbs have a service life of 50,000 hours

- Folds for storage, with the inspection surfaces together to prevent damage

Stoppers for Syringe Filling Machines

If you require a Syringe Stopper for your Syringe Filling Machine, contact us using the form below to be put in touch with an industry expert.