IBC Mixer

IBC Mixer

Durable & Easy to Sterilise

Full Material Traceability

to meet international pharma and food quality compliance regulations.

Product Specification:

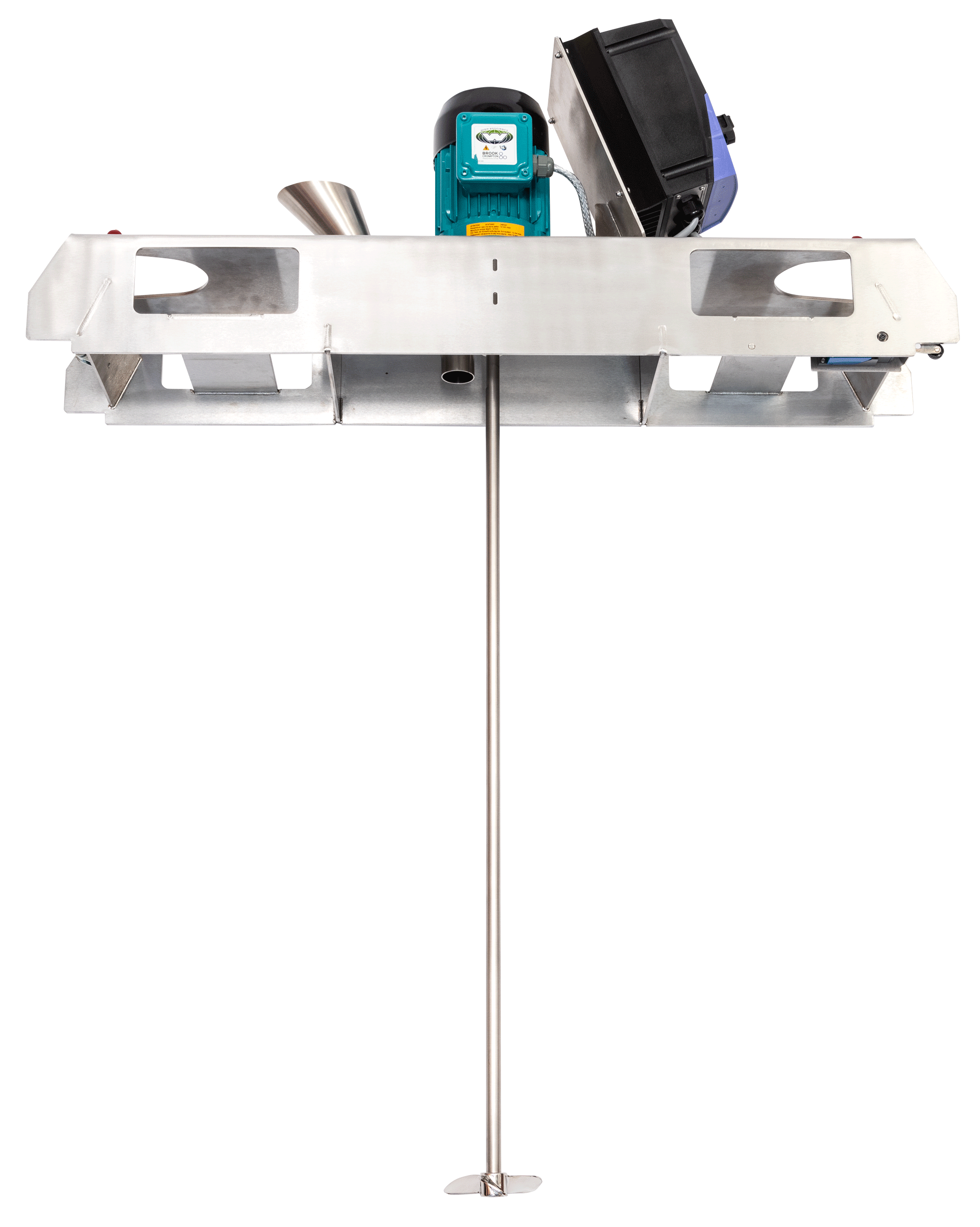

- The IBC Mixer is ideal for mixing liquid-to-liquid, oil-to-oil, free dissolving powder into liquid and keeping products in a mixed state during storage.

- Specifically designed for use upon Intermediate Bulk Containers (IBCs) with 150mm screw cap and metal outer frame.

- Manufactured from 304 grade stainless steel, with 316L pharmaceutical grade wetted parts, to guarantee no product contamination.

- Easily removable shaft and impellor. Durable, easy to sterilise and re-useable, for long service life and greater ROI.

- High level finishing - to an exceptional average surface finish of 0.5 micrometers Ra - leaves no pits or crevices for bacteria to store.

- The propellor fits through a standard 150MM screwed cap opening upon an IBC mixer.

- Variable speed drive from 420rpm to 1400 rpm

- Suitable for products with a viscosity up to 700 CPs (mPas)

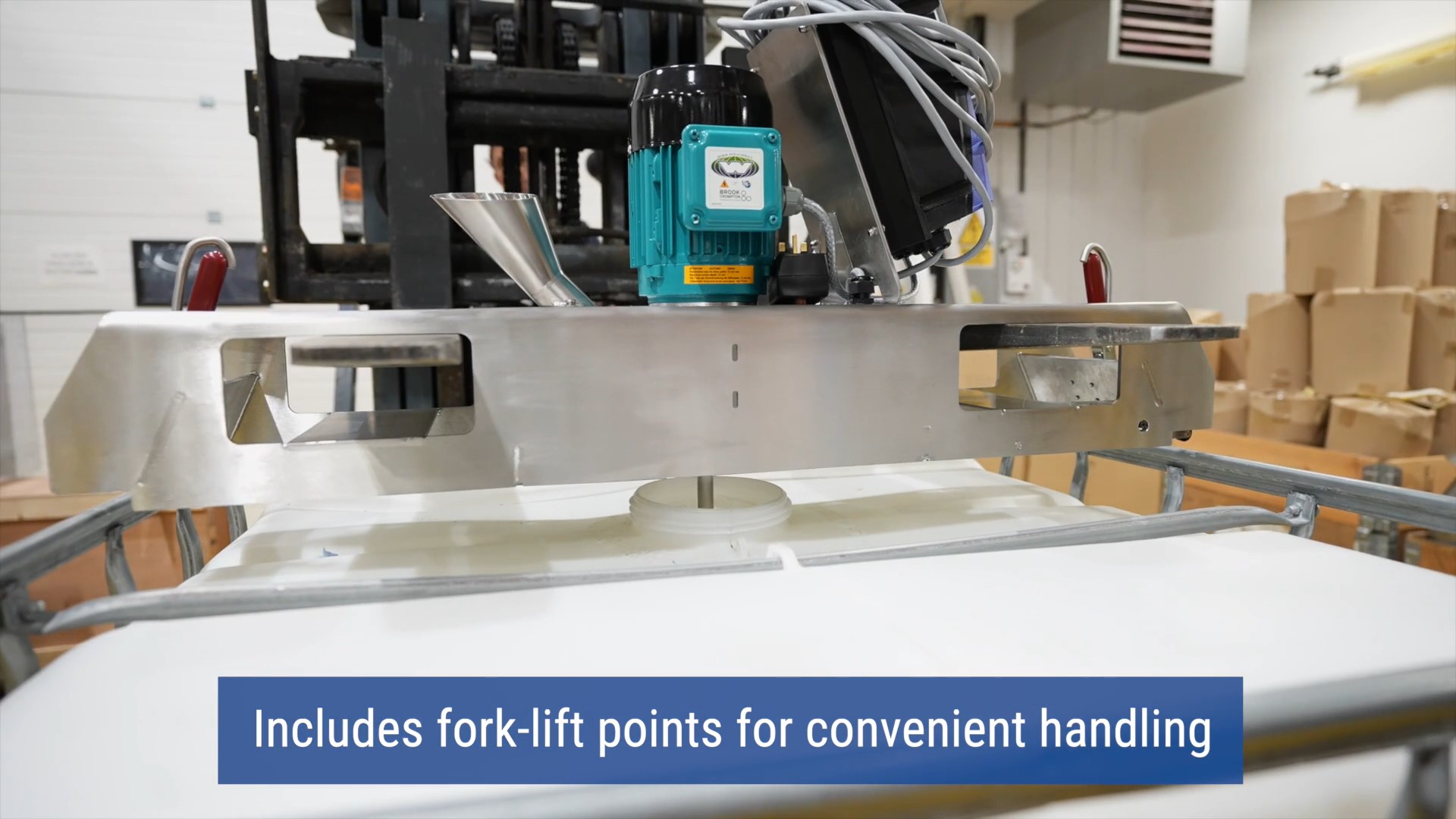

- Locates securely to standard 1000L IBC with ‘kill-switched’ toggle clamps for additional safety.

- Fully factory wired, tested & ready to use.

- Options: - Product addition chute available to conveniently add product while mixing- High-Efficiency Vortex Mixer impellor

- The IBC Mixer can be supplied with wheels for mobility.

- Full material traceability for international pharma-quality compliance: Material Grade, Surface Finish & TSE certification available upon request.

Pharma Hygiene Products also offers a Propeller Mixer, for mixing liquid-to-liquid, oil-to-oil, and free dissolving powder into liquid.

Pricing:

| Product No. | Description | Material | Price |

|---|---|---|---|

| CSP201-1000 | IBC Mixer | 304 SS | £4584 |