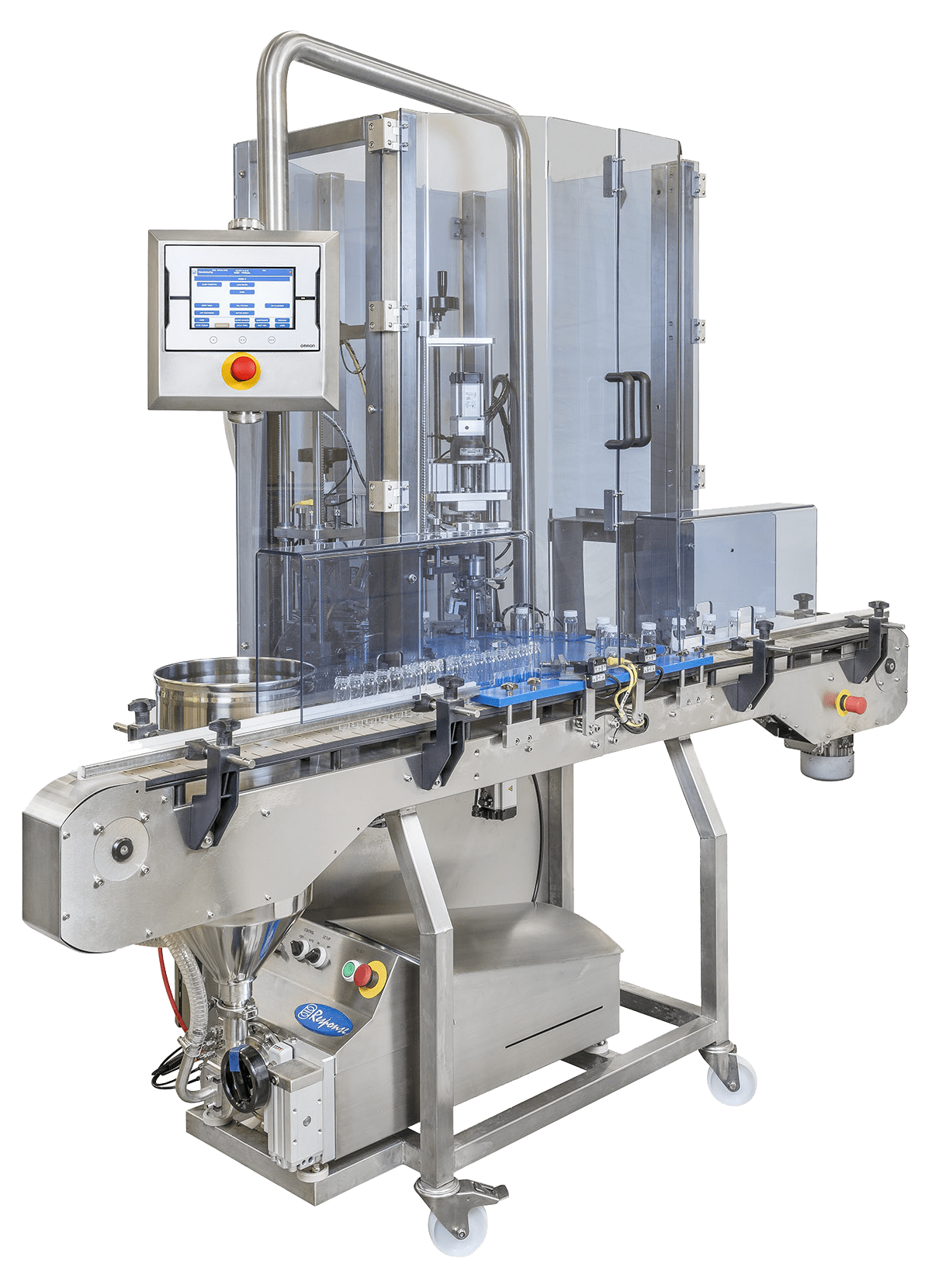

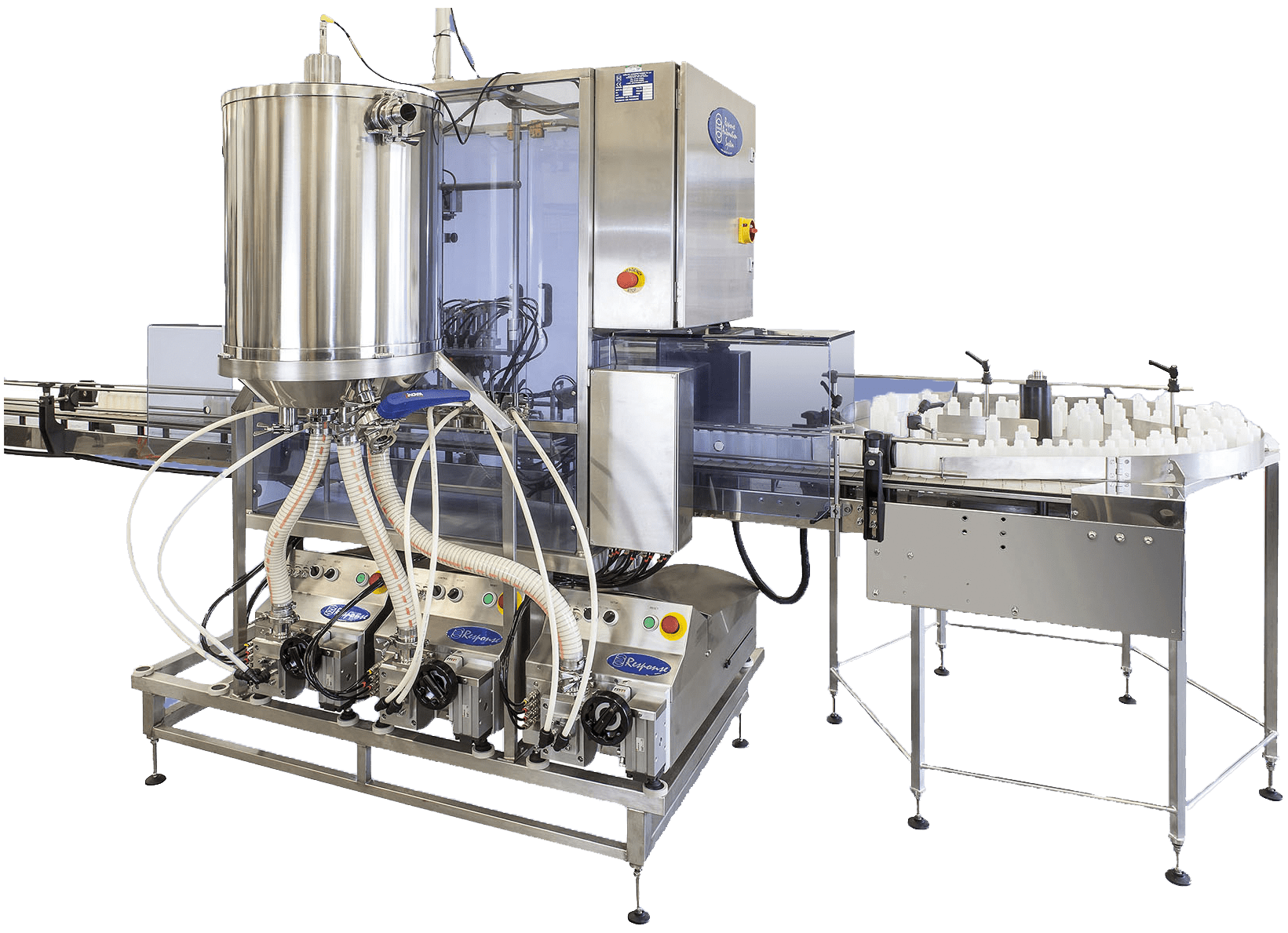

Response Automation Base

Faster Filling, Higher ROI

Reduces Waste, Increases Profitability

Quick-Strip Design Minimises Downtime

Product Specification:

- Fast filling, up to 60 containers per minute.

- Fill volumes from 5ml to 1L.

- Exceptional accuracy of up to ±0.25% reduces waste.

- 316L stainless steel / PTFE pharma and food quality compliant contact parts.

- Fills bottles, jars and screw top vials.

- Pneumatic cut-off nozzles ensure a clean fill with no dripping.

- Optional infeed and outfeed tables.

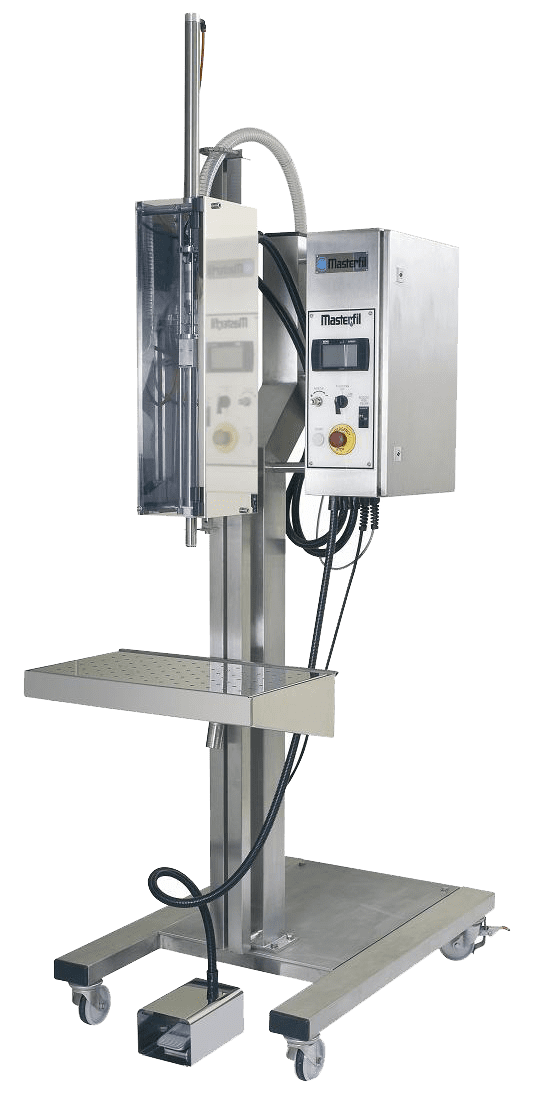

- Incorporates up to four Response Benchtop Fillers, which can also be independently used if required.

- Converts from an 8-head automatic filler into <4 benchtop filling machines within just 30 minutes

Contact us about this product

Case Studies

Barry M Cosmetics

International cosmetics giant Barry M increases productivity and versatility using Adelphi machinery

Tristel Solutions

70% increase in productivity for global disinfectants manufacturer Tristel Solutions