Noxdown

Improved Accuracy & Reduced Waste Sees Outputs Soar for In-Demand AdBlue® Manufacturer

Affable and ambitious owner Rob Vallis shares how he has built his Noxdown business “from one man and a van!” to the thriving production hub it is today…

- The Product: AdBlue® – an immensely topical, immensely popular chemical which is injected into the exhaust system of diesel powered heavy commercial vehicles and agricultural machinery – and increasingly in passenger cars.The noxious gases in the exhaust react with the ammonia in the AdBlue®, and the catalyst material contained within the exhaust, to produce nitrogen and water – two inert, harmless substances. This therefore reduces the volume of harmful gases emitted by diesel powered vehicles.

- The Customer Base: Primarily haulage firms and farmers. Noxdown are therefore currently in an extremely busy period – Spring season for farmers – and have distributed 2 million litres in March 2022 alone. “It just goes!” says Rob.

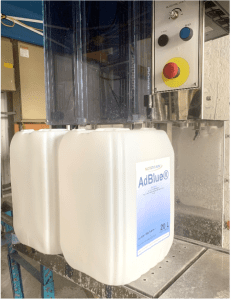

- The Containers: Whilst Noxdown works with volumes from 20L through to 26,000L tankers, this study focusses on their production of 20L containers.

“I met Andy and became aware of Adelphi Masterfil around four years ago,” Rob remembers. “At the time we were filling from a basic tap system (pictured right), which was a whole lot messier and also inaccurate, as the fill volume was detected by eye.”

Once output requirements had increased to the point where this was no longer sustainable, Rob made the leap and invested in an S5000-S semi-automatic, twin-head filling machine from Adelphi Masterfil…

The new filler (pictured below) has the benefit of preventing these potentially costly fill variations – avoiding over or under filling. The latter can be particularly costly in terms of a company’s reputation, and Rob stresses that the new machine “prevents customers ever feeling short-changed!”

A 10,000L tank is hooked up to the S5000-S, which now enables Noxdown to fill around 12 pallets of 32 x 20L containers – over 7.500L – per day!

Using the rise-while-fill nozzle option counteracts the foaming nature of the product, to maximise overall throughput speeds. Noxdown have also attached a cap basket for convenience, meaning that only one operator is needed for the whole process – capping two containers whilst the next two are filling.

Was the machine easy to set up and get to grips with? “It’s straight forward to set up and use, it does what it says on the tin,” says Rob. Being a stock machine also gave Noxdown the benefit of a significantly lower lead time than the industry standard – where possible, Adelphi Masterfil endeavours to keep machines in-stock at all times, to reduce delivery times for customers.

Adelphi Masterfil Service Technician Steve Logan undertook some minor troubleshooting during installation, as well as providing comprehensive training for Rob’s team – including how to change between different container sizes – leaving them feeling

confident to use the machine straight away.

Shared Values: The Highest Quality Guaranteed

Both Adelphi Masterfil and Noxdown adhere to stringent and independently verified ISO quality standards – “every product that leaves our factory is of certified quality,” promise Noxdown. Transacting with like-minded businesses gives confidence that the standards you expect are the standards you will receive.

Measurable Success: The Vital Stats

Noxdown has now grown from 1 to 10 members of staff. Their capacity has doubled from 3 to 6 vast product storage tanks and have added an 8,500 sq.m building to their existing 2,500 sq.m site.

The next stage? Rob enthuses that he is investigating “a new 20,000 sq.m site with 2 acres of land!” Demand for Noxdown’s AdBlue® product is increasing exponentially, and they are well positioned to meet and even exceed their future growth aspirations.

The Verdict:

“There are certain people you’re happy to deal with, and some that you’re not – Andy & Adelphi are still here, which says it all!” laughs Rob.