5 Squirrels

“In the past year we have increased our product range by 20%…It does exactly what we were promised.”

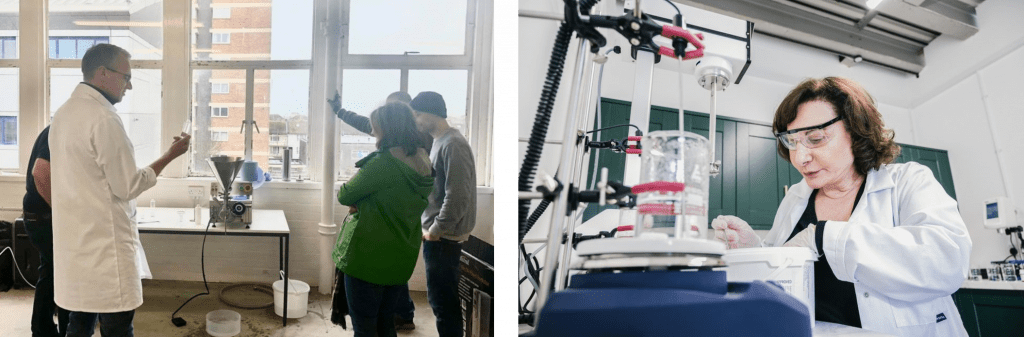

5 Squirrels supports medical aesthetics clinics to launch their own brand of signature skincare products – from formulation and testing to filling, shipping, brand design, marketing and beyond. Since their inception in 2014 the business has gone from strength to strength, gaining a reputation throughout the industry for their high quality products and extremely personalised approach.

Founding Director Gary Conroy and Production Executive Nic Crump discuss the ongoing success of their operations, one year after receiving their Response Benchtop Filler from Adelphi Manufacturing…

#StartARevolution – an Innovative Approach

5 Squirrels’ holistic approach to business – as well as formulating and filling, their support for newly launching brands extends to marketing, sales training and more – is a unique point of difference in the marketplace, and is reflected in their forward-thinking approach to production.

“We always want to increase to the next step, to prove our capabilities to customers,” says Nic. “Previously our lip pens were manufactured and filled in batches of 1kg – now we’re up to 6kg!”

“In the past year we have increased our product range by 20%, adding 3 brand new products, and we’ve increased our top customer’s range by 3 products too.” The 5 Squirrels production team has also grown from 3 to 5 people in this time – a whopping 66% increase – to cope with the increase in demand.

“Our largest batch size filled on the Response is now as high as 10,000! It does exactly what we were promised.”

Nic Crump – Production Executive

Partnering with Adelphi Manufacturing enables this vision of continuous improvement and up-scaling of production to be realised in a cost-effective way. The Response Benchtop Filler is part of an innovative, scalable range – up to four benchtop units can be incorporated into the fully automated Response Automation line as required – meaning that the initial investment is never rendered obsolete when upgrading to a fully automatic filler.

The next step for 5 Squirrels is to add infeed and outfeed tables, as well as a length of conveyor, to their benchtop machine, which will free-up operators to improve production elsewhere. This concept utilises everything from their initial investment, and any new components will still be useable in all stages of future growth.

Fast Filling – “Regularly Exceeding our Estimated Filling Schedule”

Filling up to 40 containers per minute, dependent on the product and container type, the Response Benchtop Filler was a natural and logical progression into automation for 5 Squirrels. Its versatile nozzle choices enable their full range of products – from washes and creams to serums, exfoliators and more – with equal ease.

As well as fast filling, the Response improves productivity for the 5 Squirrels production team in another way; by reducing the downtime needed for stripping, cleaning and reassembling.

“Set up and assembly is very easy,” says Nic. “Even people without a technical background get on with it perfectly, they can set up and strip down without supervision.”

The Response Benchtop Filler can be fully stripped for cleaning in as little as 3 minutes, meaning that minimal time is needed when changing between filling different product formulations.

“The only product now being filled manually is taking 26 hours to fill a small batch,” laments Nic. Adelphi were also on-hand to give advice on how 5 Squirrels can use their existing Response filler to handle even this tricky, sticky balm, and will soon be returning to run trials with the 5 Squirrels team to overcome the challenge.

Shared Values – a Focus on Quality

An exceptional quality of care and attention to detail is evident throughout the 5 Squirrels site and processes, and the business is looking to formalise this in the form of ISO certification as soon as possible. Adelphi Manufacturing are themselves ISO 9001:2015 accredited, and take pride in maintaining these superior, industry-regulated production standards.

Both businesses apply a highly personalised approach to customer service, shunning the traditional ‘one size fits all’ mentality when it comes to batch production. Both offer customisation options, modifications and even bespoke design work to ensure that the final product – be it skincare or machinery – will meet the customers’ needs precisely.

Over and above this, “the main difference with Adelphi’s quality of service was the hands-on training we received,” says Gary. Adelphi offered to help us set up the machine, and stayed whilst we completed our first fills. It wasn’t just receiving a machine in a box, with no further support.”

“When it comes to automation, we will always come to you!”