News Blog

Keep up to date with the latest news, insights and features from the Adelphi Group of Companies

Flex. Fulfil. Flourish.

December 5, 2024

The scalable filling machinery giving CMOs a competitive edge

FLEX

- From benchtop to fully automatic filling; quickly build up or break down your filling stations as required.

- Versatile for varying viscosities; handle a wide range of products without extensive retooling or downtime.

FULFIL

- From high-speed filling of your bread-and-butter range, to smaller batches of samples or pilots, and tightly controlled batches of high value products.

- Handle fluctuating client demands and seasonal spikes without overhauling your production setup.

- Meet fluctuating consumer trends and client demands, which can shift extremely quickly.

FLOURISH

- Faster product changeovers – improved turnaround times – key competitive advantage.

- Attract more clients who have diverse product requirements, including different packaging formats, volumes, or formulations – for greater profitability potential.

Within the world of Contract Manufacturing, production flexibility is paramount. The question we hear most often is “how can I be as smart as possible when investing back into my facility?”

In this article, we examine how Adelphi Manufacturing’s Response filling range is engineered to flex to the wide-ranging requirements of CMOs. We dive into how this protects your investment, creates continuity for staff and enables you to benefit from a long-lasting supplier partnership.

How to Grow Your Investment – Recommended by the ECPA

The Response Benchtop Filler is a highly regarded pneumatic filler, praised for its ease of use, hygiene and accuracy. However, what is unique about this filler is its flexibility and the potential which this adds to your operations…

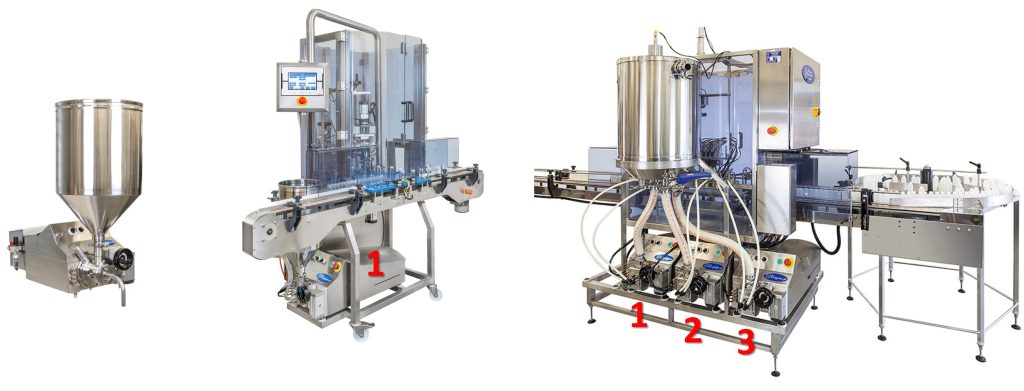

- FLEX 1: The benchtop machine is available in either single or twin head configurations, with a comprehensive range of nozzles and hoppers, allowing for unparalleled adaptability.

- FLEX 2: Your initial Response Benchtop unit can be mounted onto our Response Monobloc Filler & Capper as production requirements increase, to maximise the output potential from even the smallest production space.

- FLEX 3: Up to 4 Response Benchtop Fillers can be mounted onto the Response Automation Base, creating a fully automated line of up to 8 heads. However, if an unexpected request or order comes in, you can separate out any or all of your benchtop machines again, to fulfil multiple requirements at once.

What this means in your day-to-day, is that for production-heavy days you can run a fully automatic filling line. However, for days where a diverse portfolio of products are being produced – or fewer fills are required – the units can be separated out again with ease.

REQUEST A DEMO >>> REQUEST A QUOTATION >>>

“What we love most about the Response is the flexibility it gives to our workspace. We can adapt the layout of our machines and space as production demands, and when one machine needs cleaning, we simply wheel it away and replace it immediately with another.

Every time we’ve moved away from Adelphi’s filling machines, we’ve had issues – and you can quote me on that!” – AAK BD Foods

Creating a Powerful Partnership

In the age of automation, swapping suppliers can be as simple as a swipe on a phone screen. People are encouraged to think of goods and service suppliers – even including CMOs themselves – as dispensable and replaceable. However, at Adelphi we know the added value which long-standing relationships can bring.

Read our sister company’s article: Ways in which your supply chain can add value >>>

Conclusion

With flexible machinery, CMOs can minimize the need for separate production lines, saving on capital investment and maintenance costs. It also reduces downtime associated with changing equipment configurations.

Flexibility in machine lines empowers CMOs to serve a broader range of clients, respond more quickly to industry dynamics, and optimize operational efficiency, all while maintaining the high-quality standards your customers expect.

Adelphi are proud to partner with CMOs globally, supporting you to achieve your goals with flexible machinery and first-class customer service.

Do any of the points in this article resonate with you? You are warmly invited to contact us, to discuss current or future project requirements: 01444 472300 info@adelphi.uk.com