News Blog

Keep up to date with the latest news, insights and features from the Adelphi Group of Companies

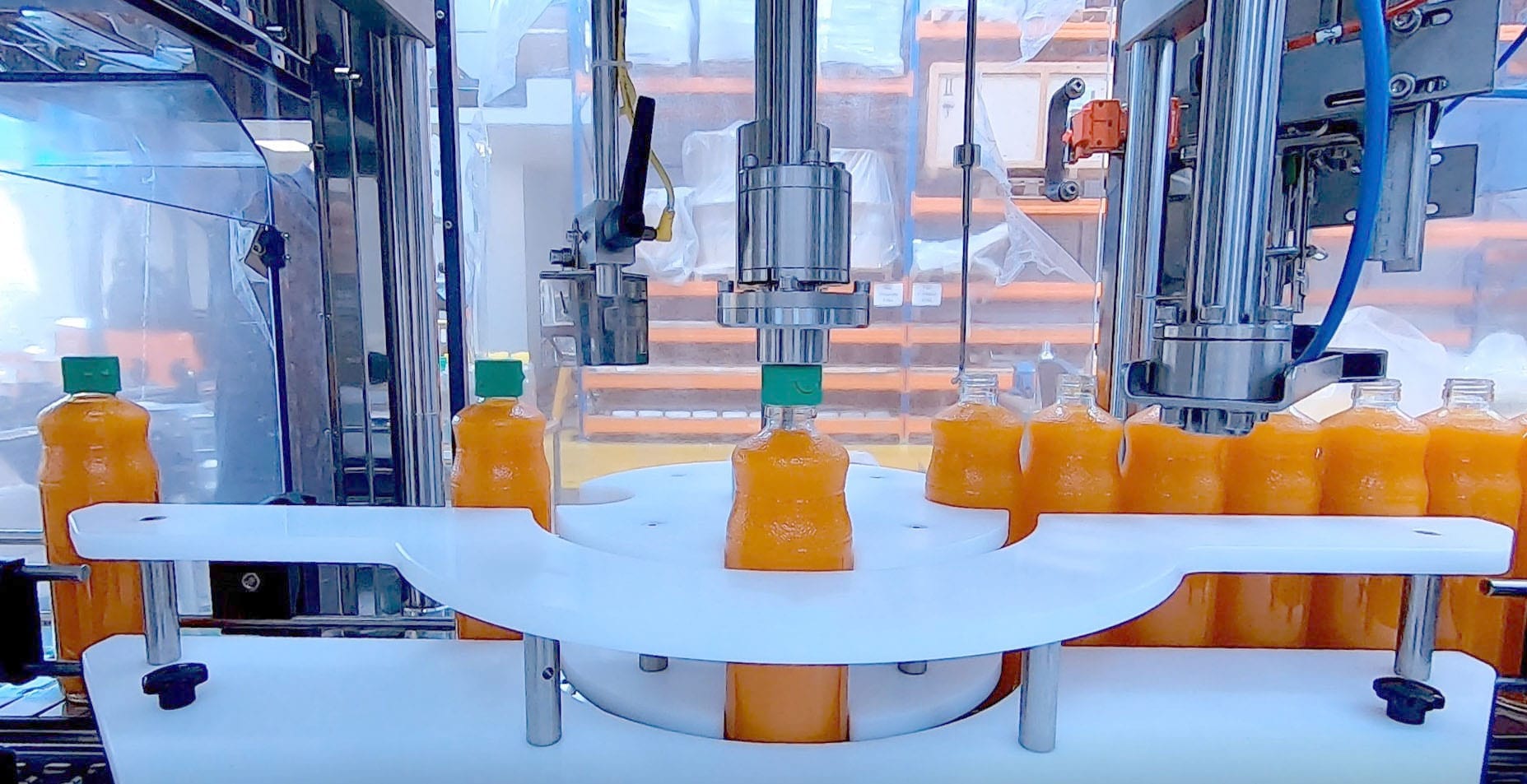

40 years in the marketplace for the Mastercap Indexing Capper

May 11, 2021

Optimise efficiency and throughput with the Mastercap Indexing Capper,

for the Chemicals, Lubricants, Personal Care, Food & Pharma Industries

Utilizing an automatic capping machine provides numerous advantages for businesses involved in packaging and bottling processes. Firstly, it significantly enhances efficiency and productivity by automating the tedious and time-consuming task of capping bottles or containers. The machine operates with precision and speed, ensuring consistent and secure seals, which is crucial for maintaining product quality and integrity. Moreover, automatic capping machines reduce labour costs, as they require minimal human intervention, allowing employees to focus on more strategic and value-added tasks within the production process. These machines are also versatile, accommodating various cap sizes and types, making them suitable for a wide range of products. Additionally, they enhance overall accuracy, minimizing the risk of spillage or wastage, thereby improving cost-effectiveness. Ultimately, by investing in an automatic capping machine, businesses can streamline their operations, increase output, and deliver high-quality products to the market efficiently.

Time-efficient, fast capping

- Up to 60 caps per minute; perfect for capping containers up to 25L.

- No container, no cap and queue sensing, to reduce waste and increase throughput.

- Cost-effective and fast single tool changeover; switch between different products and caps in minutes.

Versatile applications

- Ideal for Screw caps, Press on caps, Tamper proof caps, Sports caps, Aerosol overcaps, Angled neck containers and Inserts.

- A wide range of adjustable application torques, including high torque capability.

- Different cap feed options to suit different requirements: choose from Bulk Hopper Elevator, Disc Feeder or Vibratory Bowl Feeder.

Optimum hygienic design

- Full stainless steel construction, to allow the most thorough possible cleaning.

- Cushioned starwheel for slop prevention.

- Complete integral drip trough for contained spillages.

- Cap sterilisation option, using UV light on the cap feed chute.

Superior build quality, long service-life, greater ROI

- Stainless steel build offers exceptional chemical resistance.

- Cost-effective, precision-engineered format parts.

- Many of our machines are still fully operational over 30 years after purchase!

Market-specific features to precisely meet your requirements

- Including integration with induction sealing and inkjet printing on the outfeed.

Watch a video of the Mastercap Indexing Capper in-action >>>

Our technical team will be delighted to suggest the best specification for you. Please share with us the container and cap type and dimensions, and the capping speeds expected, so that we can prepare a quotation.