News Blog

Keep up to date with the latest news, insights and features from the Adelphi Group of Companies

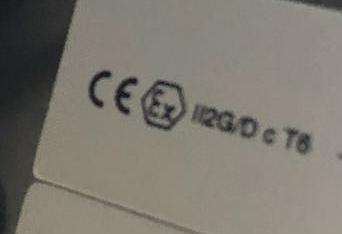

HOT TOPIC: ATEX Certified Machinery

September 24, 2018

[:en]ATEX is the name commonly given to the European Directive for controlling explosive atmospheres.

Our CAT II 2 G c T 5 (100 Degrees Celsius) Response Filler can be adapted to comply with directive 94/9/EC (also known as ‘ATEX 95’ or ‘the ATEX Equipment Directive’) on the approximation of the laws of Members States concerning equipment and protective systems intended for use in potentially explosive atmospheres.

There are three zones relating to ATEX compliance – Adelphi can make our Response base unit or automation system Zone 1 (10 – 1,000 hours per year in the explosive atmosphere) and Zone 2 (0-10 hours per year in the explosive atmosphere) compliant. We will provide the relevant documentation to support your purchase and ensure peace of mind.

Our standard Response machines are adapted for to adhere to ATEX requirements, and are made with qualified pneumatic components. We engineer-out any possible sources of static build up, and we ensure good earthing via an Earth Point included at the rear. Materials such as brass and stainless steel are used to replace some aluminium and plastic parts, and the machine is raised on different feet to allow grounding. Additionally, the hopper comes with a lid to reduce and contain fumes.

Our ATEX adapted Response fillers can come with various seal options, which we will assess to ensure compatibility with your product:

- Fluoroelastomer (VITON)

- EPDM

- Perfluoroelastomer (KALRES)

We have lodged a technical file (09XT005) with an approved body.

Please note that our ATEX machines do not cover explosive risk from dust; only gas.

To find out more about how we can help your business with ATEX compliant machinery, please don’t hesitate to get in contact with Adelphi on +44 (0)1444 472300 or email sales@adelphi.uk.com to find out how we can help.

Earth point, ATEX approved feet and the EX symbol of ATEX compliance[:]